Home » Products » Weighing Solutions » Industrial Weighing Solutions » Mettler Toledo Pallet, Pallet Truck and Mobile Scales

Increased productivity

For manufacturing, shipping, and receiving environments

Mettler Toledo Pallet, Pallet Truck and Mobile Scales

Mettler Toledo’s pallet and mobile weighing solutions are engineered to streamline logistics by integrating high-precision measurement directly into material handling equipment. These systems, ranging from stationary U-shaped scales to mobile pallet truck scales, utilize advanced strain-gauge load cell technology to deliver accurate weight data in rugged industrial environments.

By enabling weighing during transport or at the point of loading, these instruments eliminate the need for extra trips to a central scale, thereby optimizing operational efficiency and ensuring compliance with safety and trade regulations.

Advanced Integration of Load Cells in Mobile Chassis

The technical core of Mettler Toledo pallet truck scales is the integration of multi-point load cell systems directly into the chassis of the mobile vehicle. Each fork is equipped with high-precision load cells that sense the gravitational force exerted by the pallet. This design requires advanced mechanical engineering to ensure that the lifting mechanism does not interfere with the accuracy of the weight sensors. The system is calibrated to compensate for slight inclinations, ensuring that the mobile unit provides reliable measurement data even on surfaces that are not perfectly level.

Structural Integrity and Heavy-Duty Load Capacity

Mobile pallet and truck scales are constructed using reinforced steel frames designed to withstand the stresses of frequent heavy-duty lifting. Technically, the forks are manufactured to resist torsion and bending under maximum load capacities, which typically range up to 2,000 kg or more depending on the specific model. The low-profile design of the pallet scales allows for easy entry into standard Euro or industrial pallets. This structural robustness ensures that the weighing sensors remain protected from the physical impacts common in busy warehouse and shipping environments.

Digital Terminal Interfaces and Data Connectivity

Modern Mettler Toledo pallet scales are equipped with digital weighing terminals that feature high-contrast displays for visibility in industrial lighting. Technically, these terminals process the analog signals from the load cells into digital weight values using high-speed A/D converters. Many models offer wireless connectivity options, such as Bluetooth or WLAN, allowing the scale to transmit weight data directly to a Warehouse Management System (WMS) or ERP. This digital integration eliminates manual data entry and reduces the risk of transcription errors during the receiving and shipping stages.

Battery Management for Continuous Mobile Operation

A critical technical aspect of mobile pallet truck scales is their power management system. These scales are powered by heavy-duty rechargeable batteries designed for multi-shift operation. The electronics are optimized for low power consumption, featuring automated "sleep" modes when the scale is not in use. This ensures that the mobile weighing functionality is always available without the need for frequent charging. Battery status indicators are integrated into the terminal, providing the operator with real-time feedback on remaining operational time to prevent downtime.

Metrological Accuracy and Legal-for-Trade Compliance

For applications where weight dictates pricing, Mettler Toledo mobile scales are engineered to meet strict "Legal-for-Trade" certifications. Technically, this involves rigorous testing to ensure the scale maintains its accuracy class across its entire weighing range. These scales comply with international metrological standards, such as OIML or NTEP. Achieving this level of precision in a mobile unit is a significant technical feat, as it requires the sensors and the terminal to maintain calibration despite the vibrations and mechanical shocks experienced during material transport.

Ergonomic Maneuverability and Hydraulic Lifting

The design of mobile pallet scales focuses on the intersection of ergonomics and mechanical efficiency. The steering mechanism of the pallet truck scales is engineered for a high turning radius, allowing operators to maneuver heavy loads in narrow aisles. Technically, the hydraulic lift system is calibrated to require minimal manual effort, while the integrated scale adds negligible weight to the overall unit. This ensures that the addition of weighing technology does not compromise the primary function of the truck as a fast and efficient material handling tool.

Ingress Protection (IP) and Environmental Durability

Industrial environments often expose weighing equipment to dust, moisture, and chemical splashes. Mettler Toledo scales are built with specific Ingress Protection (IP) ratings, such as IP65 or higher for the load cells and terminals. Technically, this means the sensitive electronic components are sealed against the environment. For specialized industries like food or pharmaceuticals, stainless steel versions are available that can withstand washdown procedures. This protection is vital for maintaining long-term sensor accuracy and preventing corrosion in harsh operating conditions.

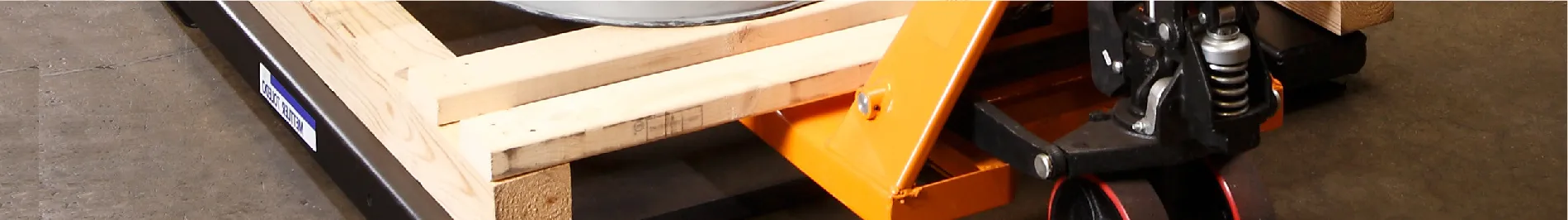

Versatile U-Shape Design for Streamlined Loading

Pallet scales are technically adaptable to various pallet dimensions and types, including stringer and block pallets. The stationary pallet scales often feature a U-shape design, which allows a pallet truck to drive directly into the weighing area to deposit the load without the need for a ramp. This "drive-in" capability optimizes space in the warehouse. Whether mobile or stationary, the scales are designed to provide a uniform response regardless of the load's center of gravity, ensuring consistent results even if the pallet is not perfectly centered on the forks.

Read more about Mettler Toledo Pallet, Pallet Truck and Mobile Scales

.webp)