iC Software

Capture Data, Visualize & Interpret Experiments, Report Results

Mettler Toledo iC Software

Data interpretation helps build understanding of how a reaction works or how a process is impacted by a parameter change. iC Software transforms experimental data into important process knowledge.

Capture, prepare and share data with iC Data Center, determine process variables with iControl and iControl RC1e, analyze reactions with iC IR, optimize reactions with iC Kinetics, analyze particle size and shape with iC FBRM, iC Vision, and iC PVM , and transfer processes from the lab to production with iC Process.

Extract critical information about key reaction species and gain in-depth reaction understanding with iC IR. Results are delivered in real time, streamlining analysis and eliminating the need for offline sampling. During an experiment, EasyMax HFCal and OptiMax HFCal collect and store a wealth of information. iControl software automatically calculates and reports heat transfer data, specific heat of the reaction mass, heat flow and reaction enthalpies – resulting in faster process development and safer scale-up.

Unified Interface and Seamless Data Exchange

The iC Software Suite implements a "common look and feel" across all its modules, ensuring that researchers can transition between different analytical techniques with minimal training. Technically, the suite acts as a single software framework where data from a ReactIR (controlled by iC IR) can be overlaid with reactor data from an EasyMax (controlled by iControl). This effortless data exchange allows users to view temperature, dosing, and infrared trends on a single timeline, providing a multi-dimensional view of the reaction that is essential for accurate mechanistic studies.

Intelligent Reaction Analysis with iC IR

iC IR is specifically engineered for in situ FTIR spectroscopy, converting raw spectral data into meaningful reaction profiles. The software features "One Click™ Reaction Profiling," which utilizes advanced algorithms to automatically identify key infrared trends and functional group changes. By eliminating the manual effort of baseline correction and peak integration, iC IR allows scientists to focus on interpreting the chemical significance of intermediates and reaction endpoints. It provides expert-level methodologies that simplify complex data for all users, regardless of their spectroscopy background.

Comprehensive Reactor Control via iControl

As the primary interface for automated lab reactors, iControl provides the technical foundation for executing precise experimental recipes. Users can program complex sequences for heating, stirring, and liquid dosing through a graphical drag-and-drop interface. The software records every event and sensor reading with high temporal resolution, ensuring that the physical environment of the reaction is fully documented. iControl also integrates with calorimetry modules (HFCal) to automatically calculate heat flow and reaction enthalpies, providing critical safety data during scale-up.

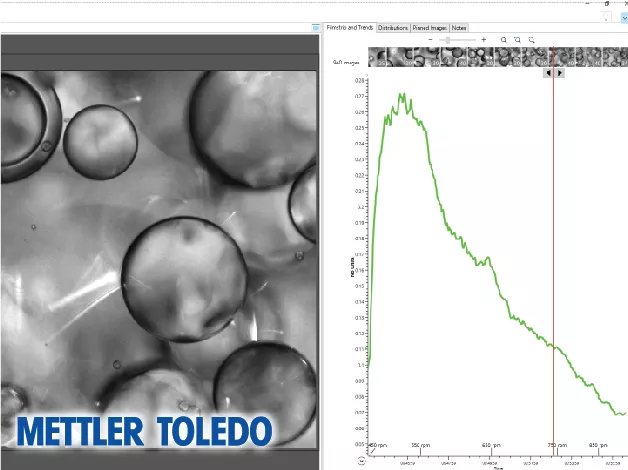

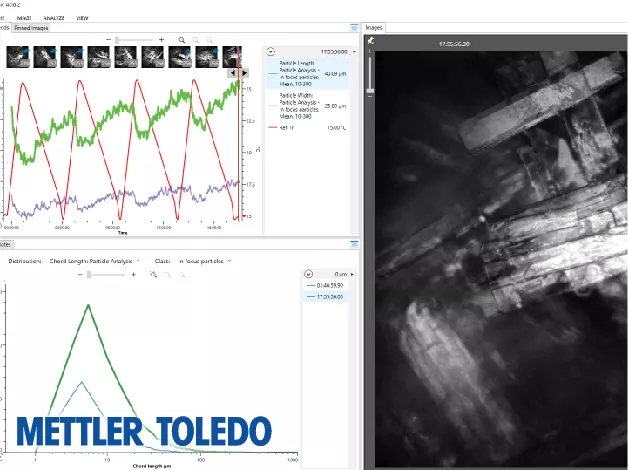

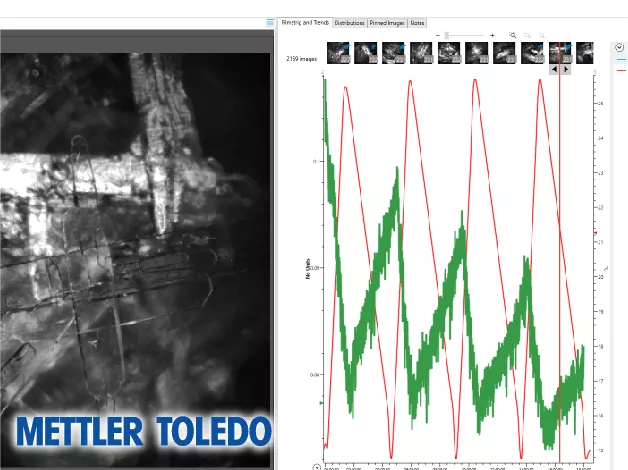

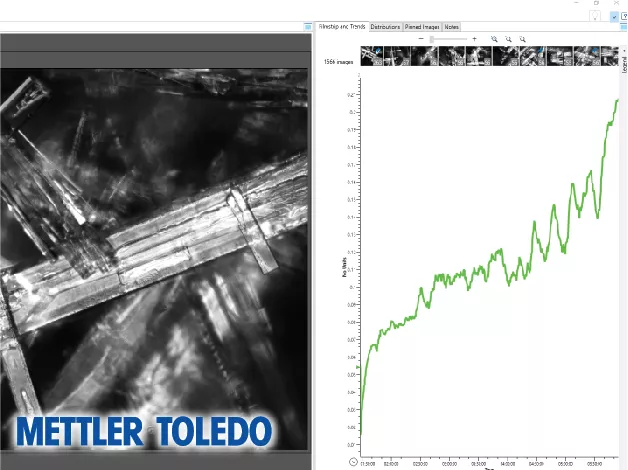

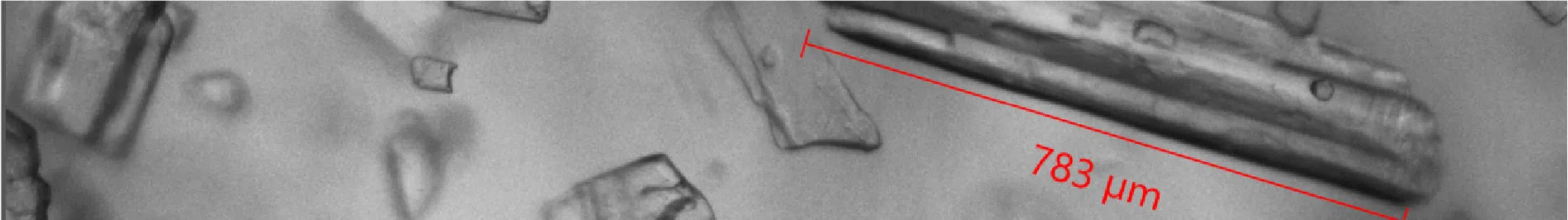

Particle System Dynamics with iC FBRM and iC Vision

For crystallization and particle engineering, the iC Suite offers specialized tools like iC FBRM and iC Vision. iC FBRM quantifies particle size and count in real-time using FBRM (Focused Beam Reflectance Measurement) technology, while iC Vision provides automated image analysis for probe-based microscopy. These applications allow researchers to see how changing process variables—such as cooling rates or agitation—directly impact crystal morphology and chord length distributions. The ability to overlay these particle trends with chemical data from iC IR offers a holistic view of the crystallization process.

Centralized Knowledge Management with iC Data Center

iC Data Center technically addresses the challenge of laboratory data loss by automatically capturing and archiving data from all connected instruments. It identifies when an experiment has finished and moves the data to a secure, centralized file store. Beyond simple storage, it prepares the data for ingestion by Electronic Lab Notebooks (ELNs) or LIMS. This technical automation ensures that institutional knowledge is preserved and that researchers can retrieve past experiments for comparison, improving long-term productivity and supporting regulatory compliance by maintaining an unbroken data chain.

Accelerated Process Development via iC Kinetics

To move from qualitative understanding to quantitative models, the iC Suite integrates iC Kinetics. This module uses the high-frequency data captured during experiments to calculate reaction rates and activation energies. Technically, it fits experimental trends to kinetic models, allowing researchers to simulate how a reaction will behave under different conditions. This predictive capability is vital for optimizing yields and minimizing byproduct formation, effectively reducing the number of experiments required to finalize a robust manufacturing process.

Lab-to-Plant Technology Transfer with iC Process

The transition from laboratory research to production is facilitated by iC Process. This specialized application allows for the deployment of validated analytical methods, developed in iC IR, directly onto the manufacturing floor. It provides a simplified interface for plant operators while maintaining robust communication with Distributed Control Systems (DCS) via industry-standard protocols like Modbus or OPC UA. This ensures that the critical control parameters (CPPs) established in the lab are monitored with the same level of technical precision during full-scale production.

Maintenance and Security through iC Software Care

To ensure technical reliability and data integrity, Mettler Toledo provides iC Software Care, a subscription-based maintenance plan. This service guarantees that laboratories always have access to the latest software versions, which include new features, security patches, and compatibility updates for the latest Windows operating systems. By keeping the iC Suite current, organizations minimize total cost of ownership and ensure that their analytical tools remain compliant with evolving IT security standards and laboratory regulations.

Read more about Mettler Toledo iC Software