Home » Products » Operational Environment Solutions » Bio-Decontamination Systems » Bioquell Qube – Pharmaceutical Isolator

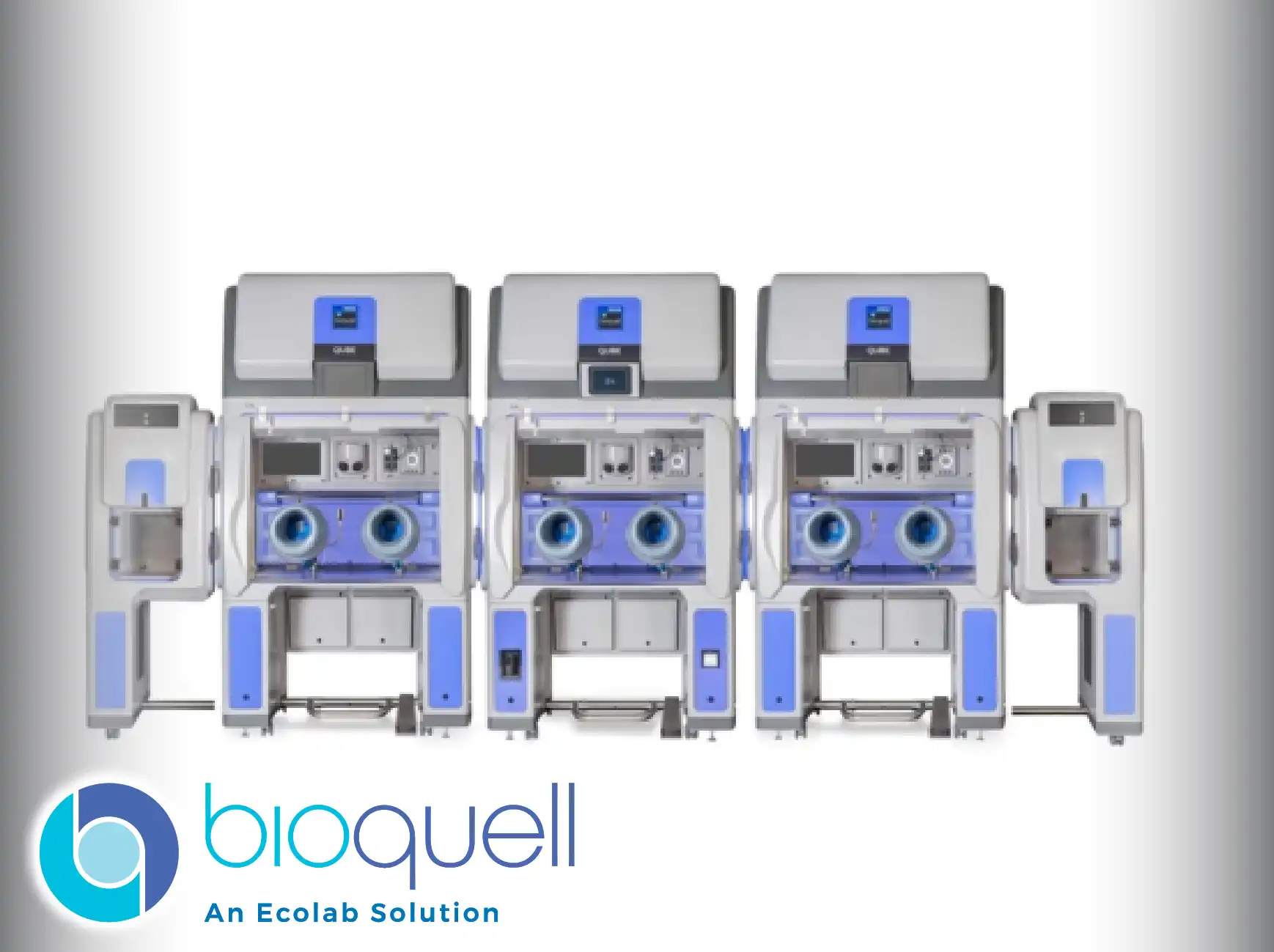

Customizable Pharmaceutical Isolator

With Integrated Vapor Technology

Bioquell Qube – Pharmaceutical Isolator

Engineered to support modern, high-value operations such as small batch production and cytotoxic preparation, the system minimizes the risk of product cross-contamination and environmental ingress. The tight integration of the vapor technology ensures that decontamination cycles are swift and fully validated, safeguarding the integrity of sensitive materials and biological products.

This isolator's customizable nature allows it to be tailored to specific workflow demands, offering flexibility not commonly found in traditional aseptic equipment. By focusing on superior bio-decontamination alongside ergonomic design, the Qube provides a dependable barrier that protects both the product and the operator, enhancing both safety and workflow efficiency.

Maintaining a continuously Aseptic environment is a core regulatory challenge; this isolator addresses it by fully containing the Hydrogen Peroxide Vapor process. This containment strategy prevents environmental air exchange until the workspace is certified sterile, providing an unparalleled level of process control.

The system's adaptability is crucial for facilities engaged in Small Batch production and novel therapies like gene/cell work, where dedicated equipment for varied protocols is necessary. Its customizable format allows tailoring to specific material transfer and manipulation requirements, optimizing throughput for specialized, high-cost materials.

Addressing the risk of Cross-Contamination is paramount, especially when handling potent compounds or multiple product lines. The integrated vapor technology ensures rapid, comprehensive surface sanitization between batches, minimizing the financial and regulatory exposure associated with product mix-up.

Traditional isolators often suffer from long decontamination cycles, leading to significant process Bottlenecks; the integrated vapor technology is optimized for speed and efficacy. This quick-cycle capability is essential for increasing the number of sterility tests or production runs achievable in a standard workday.

The unique Design of the unit offers operational advantages by improving visibility and access within the working area. This ergonomic focus reduces operator strain and the potential for manipulation errors, which are common issues in less thoughtfully engineered containment systems.

For regulatory certainty, the system provides fully Validated bio-decontamination cycles that are repeatable and documentable. This feature simplifies the process of achieving and maintaining regulatory approval, directly solving the problem of audit preparedness.

Handling hazardous materials, such as those required for Cytotoxic preparation, demands absolute containment. The sealed isolator environment, combined with the power of the vapor process, provides a verifiable, safe working space for operators, mitigating personnel exposure risks.

The seamless Integration of the vapor generator within the isolator frame eliminates external hardware and complex connections, which are common points of failure or maintenance issues in modular systems. This self-contained approach simplifies maintenance and ensures system reliability and uptime.

Click here to know more about Bioquell products and solutions