Home » Products » Material Preparation, Analysis, and Testing » Hardness Testing Systems » Buehler DiaMet Software

Analysis Software

Automated Hardness Data Acquisition

Buehler DiaMet Software

Comprehensive Hardness Instrument Management The DiaMet Hardness Testing Software serves as a comprehensive digital ecosystem designed to manage and execute all facets of the hardness instrument operation. It enables automated testing sequences, precise measurement acquisition, and standardized report generation, significantly minimizing the requirement for constant operator intervention during repetitive tasks.

Automation and Standards Compliance The software is engineered for maximum versatility and regulatory alignment, supporting a wide spectrum of fundamental hardness evaluation techniques such as Macro-Vickers, Micro-Vickers, Knoop, Rockwell, Superficial Rockwell, and Brinell. Beyond standard methods, it incorporates K1c fracture assessments and allows for immediate hardness conversion into alternative scales. Crucially, its design prioritizes simplicity in automation, offering swift operation that meets the stringent requirements of ISO and ASTM standards, ensuring that all resulting data is traceable, standardized, and immediately compliant for industrial reporting.

Eradicating Manual Setup Complexity

The system simplifies automated testing initiation, requiring minimal interaction (described as four clicks) to begin a test run, directly challenging the assumption that high automation correlates with operational difficulty. This focus on swift and uncomplicated operation ensures even new personnel can quickly execute complex testing protocols accurately. Furthermore, the ability to utilize pre-configured shortcuts for frequently performed tests optimizes the overall workflow, dramatically reducing non-testing preparation time.

Ensuring Test Cycle Speed and Efficiency

Engineered for speed, the integrated software-hardware solution translates into the fastest test cycle available, capable of readiness in five seconds or less. This accelerated testing speed provides laboratories with enhanced control over internal process monitoring and validation. Users maintain flexibility through full manual controls for bypassing programmed sequences or leverage the system's inherent velocity with optimized, rapid setup for recurring measurements.

Centralizing Data and Resource Management

The introduction of a streamlined shared database capability allows facility managers to network all connected hardness testers. This central hub facilitates the sharing of common programs, testing jobs, and template files across the entire lab environment. This consolidation ensures process uniformity and enables data review and report generation to be performed remotely on a desktop workstation without interrupting the active operation of the testing equipment.

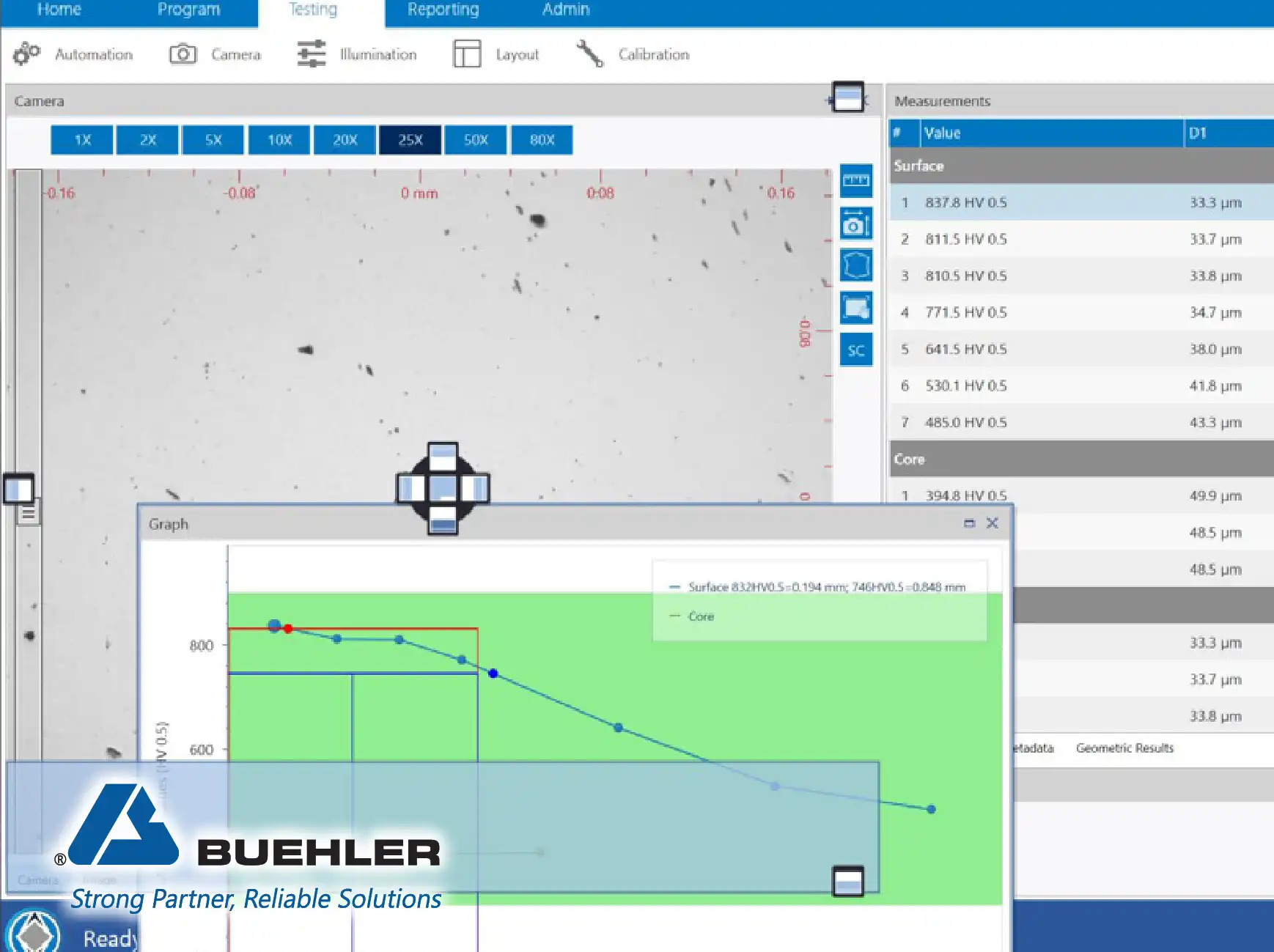

Precision in Indent Measurement and Image Acquisition

The software integrates several image control features to maximize measurement precision. Capabilities like seamless auto-focus, auto illumination, and digital zoom ensure that the indentations are captured under optimal conditions regardless of the material surface or operator skill. Advanced features like auto measurement further eliminate subjective judgment by providing algorithmic assessment of the indentation size, guaranteeing consistent and high-integrity data.

Advanced Pattern Generation and Testing

Specialized functions such as Pattern Programming and dedicated testing modules for Case Hardness Depth (CHD) calculations, Jominy testing, Weld testing, and Gear testing are integrated directly into the platform. This systematic approach automates the placement of complex indentation arrays, eliminating the requirement for manual XY-stage movements and complex coordinate entry, thus minimizing human variability in standardized pattern execution.

Comprehensive Specimen Analysis and Mapping

The software supports advanced spatial analysis techniques including Hardness Mapping, Contour Scan, and Stitching functionality. These features automatically navigate the XY-stage across the specimen surface, acquiring multiple images and assembling them into a coherent, large-area representation. This provides a complete visual and quantitative distribution of hardness across the entire sample, enabling detailed evaluation of structural gradients and material homogeneity.

Optimized User Interaction and Interface Design

Designed specifically to be simple and smart to work with, the interface is touch-optimized, utilizing clean design and intuitive gestures for navigation. Virtual tabs provide quick access to core functions (Home, Program, Testing, Reporting). Furthermore, continuous and comprehensive feedback is displayed on the status bar, providing the operator with clear, real-time status of the testing instrument, thereby improving operational awareness and minimizing errors.

Managing Complex and Multi-Specimen Batches

The system facilitates the efficient handling of diverse testing loads through Multi Sample and Multi-fold Sample Templates capabilities. The integrated XY-stage control allows for the programmed testing of multiple specimens loaded simultaneously, or the execution of complex testing routines across various zones on a single sample, dramatically improving efficiency when processing batches that require varied testing methods or multiple points of analysis.

Click here to know more about Buehler products

.webp)