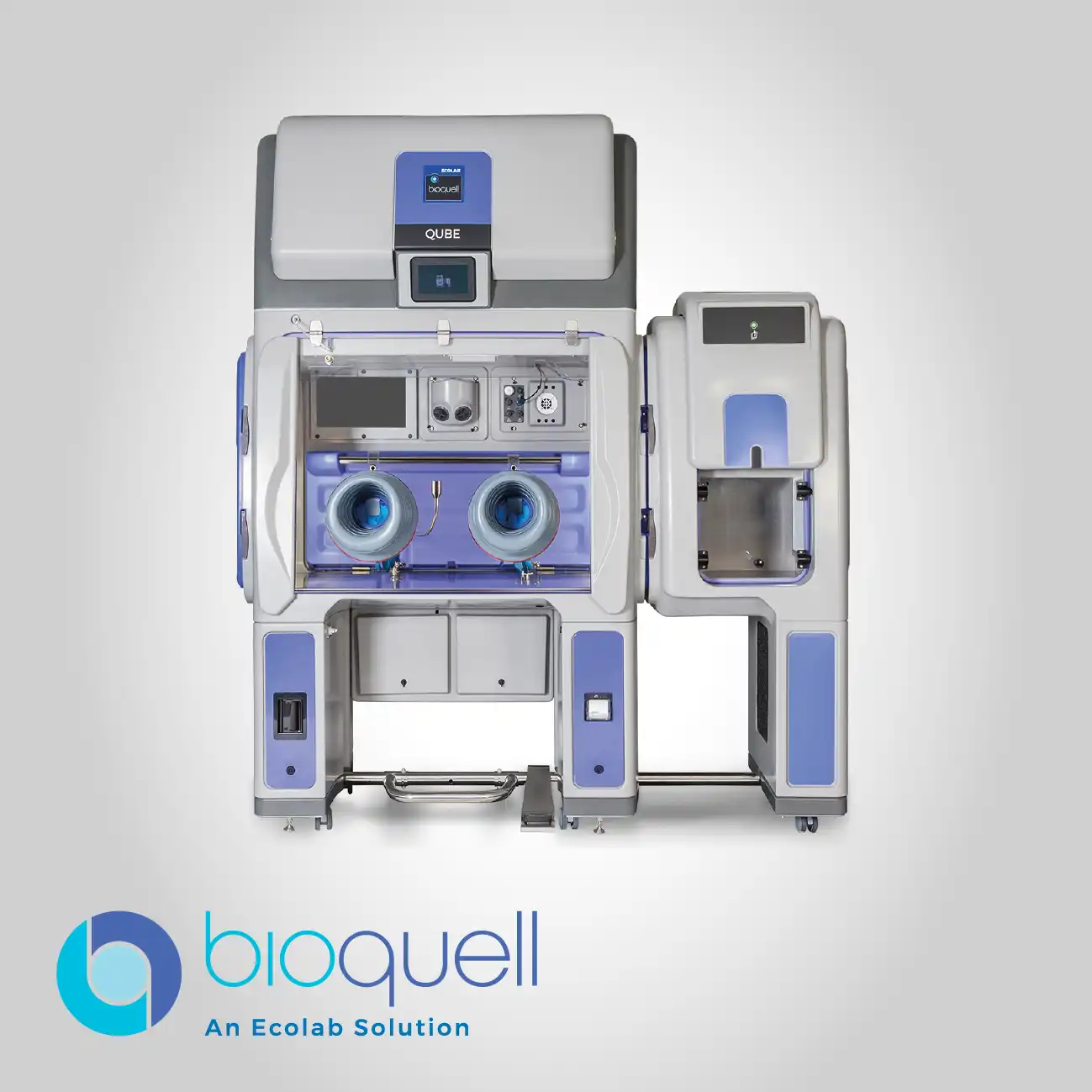

Fixed Compact Decontamination System

For Airlocks and Small Research Areas

Bioquell SeQure

This system is ideally suited for controlling contamination within pass-throughs, material airlocks, and small research areas, typically spaces under 150 cubic meters. Its ability to achieve a 6-log sporicidal kill ensures that items entering or leaving a high-grade environment are fully sanitized, eliminating a major pathway for microbial transfer and safeguarding internal environments.

The unit's fixed and compact nature simplifies its integration into existing facility infrastructure, minimizing footprint while maximizing its utility for critical operations such as viral and bacterial vector work. The integrated setup and validated cycles provide facility managers with a dependable, automated protocol for environmental sanitization, reducing reliance on less reliable manual methods.

The risk of Ingress contamination through essential material transfer points is a major concern; this system, being ideal for airlocks, automates the sanitization process at the interface. This fixed, automated function removes the dependency on operator consistency for sterilizing transferred items.

For smaller, highly critical research spaces, the complexity and size of traditional decontamination equipment present an installation Footprint problem. This wall-mounted, compact unit is specifically designed to fit into restrictive environments, solving the space constraint issue without compromising efficacy.

The system's fully Validated cycles directly address the regulatory requirement for verifiable decontamination protocols in biosecure environments. The automated, consistent execution of the cycle provides the necessary audit trail for regulatory bodies, reducing the burden of manual process validation.

Managing contamination in rooms under a specific volume (150 cubic Meters) often requires tailored solutions; this unit is scaled precisely for this range. Its optimized output ensures rapid gas distribution and removal in small areas, preventing damage or lengthy aeration times associated with oversized generators.

In high-value applications like viral and bacterial Vector work, even minimal contamination can destroy a research batch. The system's use of 6-log sporicidal vapor ensures maximum kill assurance on all exposed surfaces within the pass-through or chamber, protecting valuable assets.

By being permanently Fixed and integrated, the system provides a consistent point-of-use decontamination solution that is always ready. This contrasts with mobile units that require setup and breakdown, eliminating operational delays and maximizing facility utility time.

The wall-mounted Installation is a feature that simplifies facility cleaning and maintenance around the unit, reducing the risk of microbial accumulation in hard-to-reach areas. This architectural integration promotes superior facility hygiene compared to floor-standing equipment.

The SeQure helps facilities achieve high-level Biosecurity by ensuring that all materials passing through its operational zone are biologically inert. This systematic approach to controlling environmental sources prevents the spread of adventitious agents between segregated laboratory areas.

Click here to know more about Bioquell products and solutions