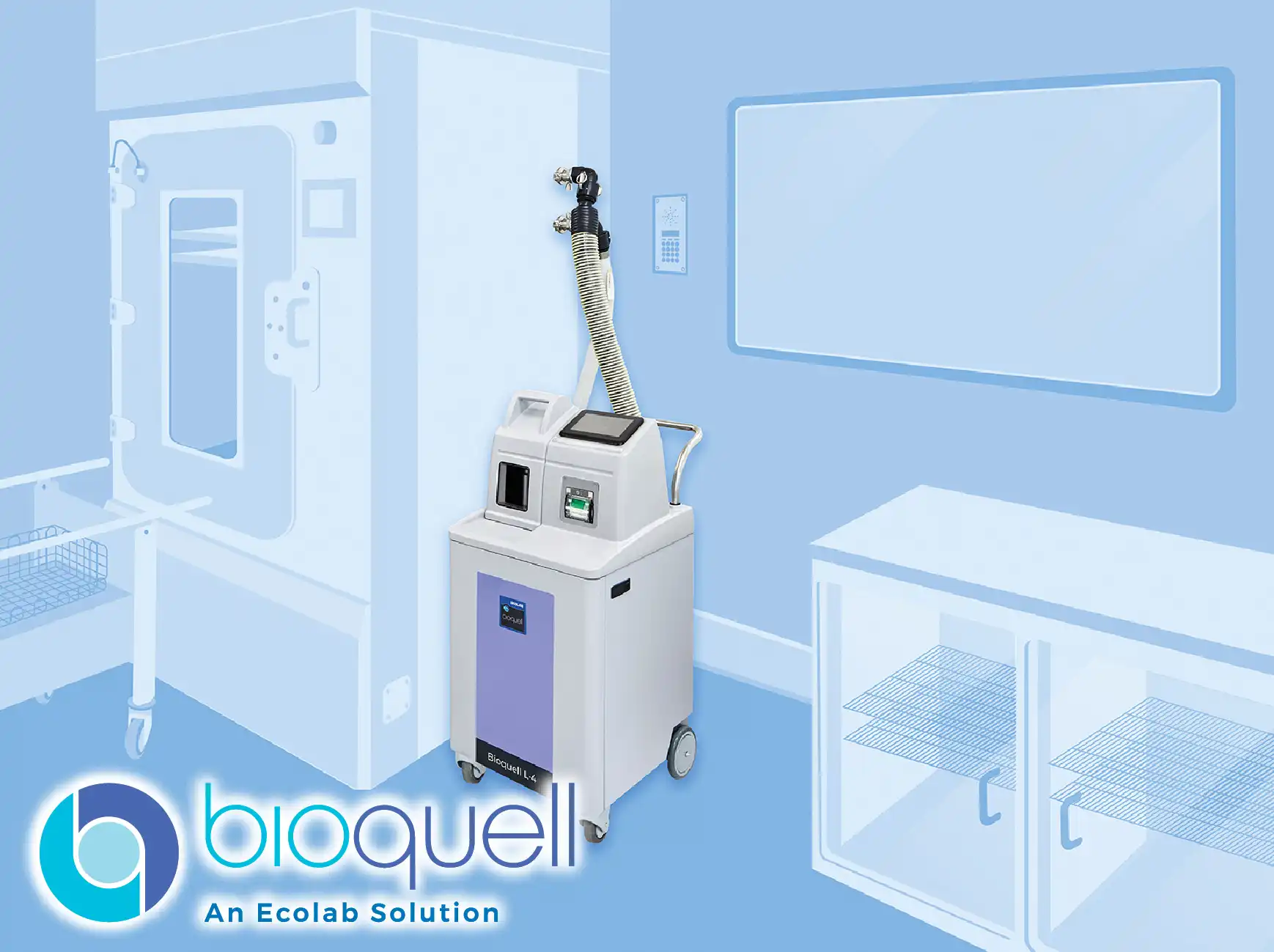

Versatile Multipurpose H₂O₂ Vapor Generator

For Equipment and Room Decontamination

Bioquell L-4

The L-4 serves as a highly versatile, multipurpose generator designed to produce Hydrogen Peroxide Vapor for bio-decontamination across a comprehensive spectrum of critical equipment and spaces. Its functionality scales seamlessly, enabling its use for sanitizing the internal surfaces of small, enclosed systems, such as isolators and bio-safety cabinets, up to the volumes of larger production rooms and dedicated laboratory spaces. This single-platform flexibility is engineered to maximize facility asset utilization and simplify standardized decontamination protocols.

This vapor generator provides essential support for maintaining the sterility of specialized laboratory equipment, including Restricted-Access Barrier Systems (RABS), freeze dryers (lyophilizers), and cage/rack washers. By delivering a 6-log sporicidal kill, it ensures regulatory compliance for surface sterilization within these complex systems, which are difficult to address with traditional liquid cleaning methods.

The versatility of the unit addresses the operational challenge of requiring multiple decontamination devices for different size applications. Its multipurpose design allows facilities to consolidate their decontamination inventory, standardizing training and maintenance procedures across all targeted enclosed systems and room decontamination requirements.

Addressing the difficulty of validating the internal surfaces of complex Equipment like freeze dryers and RABS is a key challenge; the vapor distribution technology ensures full saturation and sporicidal kill in these hard-to-reach internal volumes. This capability significantly de-risks the compliance of complex instruments.

The unit's ability to transition from small enclosure sterilization to large Room decontamination solves the logistical problem of managing multiple, specialized machines. This scalability allows for a unified approach to decontamination management throughout the entire facility ecosystem.

In systems requiring highly controlled environments, such as Isolators and Bio-Safety Cabinets, the vapor process provides a residue-free and rapid sanitization. The H₂O₂ Vapor rapidly breaks down into water and oxygen, ensuring no chemical carry-over that could harm sensitive processes or products.

The system's broad application range, covering Enclosed Systems like incubators and filter bank enclosures, allows facilities to streamline their validation protocols. Using a single generator platform simplifies the documentation and revalidation effort required across varied equipment types.

Maintaining hygiene in animal research environments, specifically Cage Washers and racks, requires a robust, high-level disinfectant. The H₂O₂ vapor offers a dry process that effectively decontaminates the machinery itself, preventing microbial buildup that could compromise animal welfare or research data.

The challenge of effectively sterilizing Lyophilizers (Freeze Dryers), which are intricate and difficult to access, is met by the penetrating nature of the vapor. The system ensures that the entire internal chamber, including shelves and condenser areas, achieves a consistent 6-log reduction.

Its Multipurpose capability directly addresses the financial and inventory cost associated with purchasing and maintaining separate specialized units for each application size. This singular focus promotes greater return on investment.

The system facilitates simplified Validation across its application spectrum because the core technology and sporicidal agent remain consistent. This standardization reduces the complexity of audit trails and documentation for facility-wide decontamination operations.

Click here to know more about Bioquell products and solutions