.webp)

Home » Products » Microbiology Laboratory Solutions » Media Preparation and Dispensing » INTEGRA Media Sterilizer (MEDIACLAVE)

Dedicated Media Sterilizer

For Rapid and Reproducible Culture Media Preparation

INTEGRA Media Sterilizer (MEDIACLAVE)

One of MEDIACLAVE’s pivotal features is its ability to minimize the thermal stress on the culture medium, a common issue with traditional autoclaves where prolonged cooling impairs agar fertility. The system achieves this through powerful heating elements for fast media processing and an efficient plate heat exchanger that facilitates rapid cooling down to the dispensing temperature. Additionally, permanent magnetic stirring ensures homogenous temperature distribution throughout the entire batch, preventing localized overheating and degradation of heat-sensitive components.

Safety and operational efficiency are paramount, as MEDIACLAVE is equipped with multiple independent monitoring systems for pressure and temperature, guaranteeing the highest safety standards. The intuitive graphical user interface and simple programming simplify operation for all users. Furthermore, it supports process documentation and validation, allowing all sterilization cycle data to be stored electronically or printed, ensuring compliance with strict quality control requirements like FDA (21 CFR Part 11) / EU (GMP Annex 11) regulations.

Traditional media preparation in general-purpose autoclaves is time-consuming, often requiring multiple steps of dissolution, sterilization, and cooling. MEDIACLAVE integrates formulation and sterilization into a single, much shorter process, drastically reducing the overall time needed for media availability.

Inconsistent media quality is a major drawback of standard autoclaving, often due to uneven heat distribution and prolonged exposure to high temperatures. Permanent magnetic stirring within the vessel guarantees homogenous temperature throughout the batch, preserving the fertility and quality of the agar.

Excessive heat exposure during the slow cooling phase in conventional autoclaves can significantly impair the growth characteristics and performance of the culture medium. MEDIACLAVE employs an efficient plate heat exchanger for rapid cooling, minimizing thermal stress on heat-sensitive components.

Opening and closing the vessel lid on conventional autoclaves often requires bolts or tools, increasing handling time and potential for operator injury. MEDIACLAVE features a simplified twist-to-open vessel access, enhancing user convenience and safety.

Standard autoclaves often monitor temperature only at a single reference point, leading to variations in actual sterilization temperature within the media. MEDIACLAVE uses a precise Pt-1000 temperature probe and microprocessor control to accurately monitor and regulate the temperature within the medium itself.

The absence of detailed sterilization records in manual workflows makes validation and compliance with strict quality control bodies difficult. MEDIACLAVE allows for electronic process documentation via a USB port, automatically adding a digital signature for regulatory compliance (e.g., FDA 21 CFR Part 11).

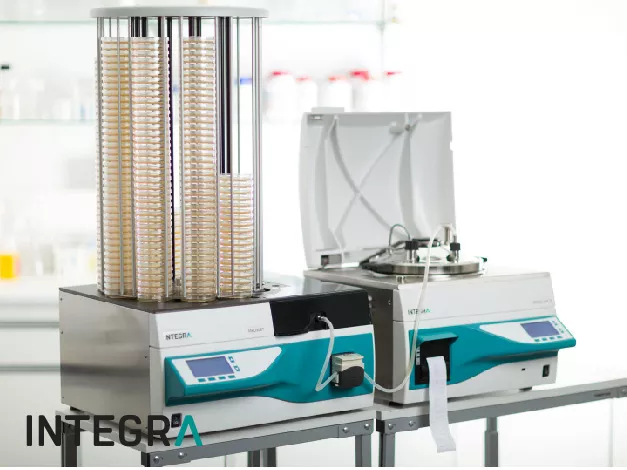

Handling large volumes of hot media manually after sterilization is labor-intensive and poses burn risks. MEDIACLAVE can be directly connected to the MEDIAJET or DOSE IT systems, allowing for pressure dispensing of the sterilized medium into plates or bottles, automating the final, risky step.

Contamination of the cooling water system with the culture medium is a potential risk in some designs. The MEDIACLAVE features a separation between the cooling water system and the sterilization chamber, greatly reducing the probability of culture media contamination.

Read more about INTEGRA products and solutions

.webp)

.webp)