PTG-S5

Automated Powder Flow Analyzer

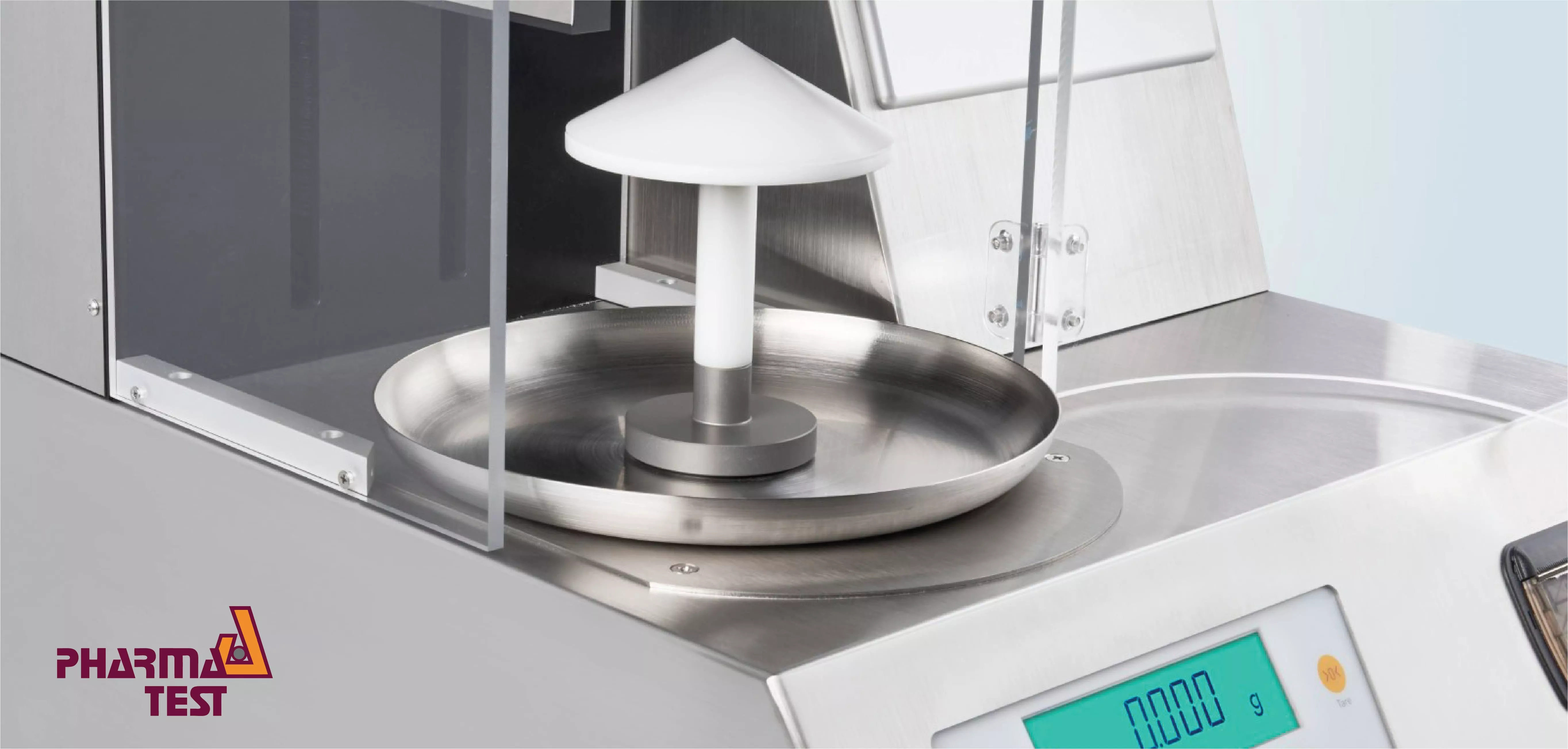

NEW PTG-S5 Automated Powder Flow Analyzer from Pharma Test

The PTG-S5 from Pharma Test automated powder flow analyzer is designed for the measurement of the flow behavior of powders and granules in compliance with the EP <2.9.36>, EP <2.9.16>, USP <1174> Pharmacopoeia and ISO 4324 standards. This instrument determines the powder flow time, the powder cone angle of the collected powder mound, the volume, the density and the weight of the powder cone. Moreover, the EP “flowability” result is calculated by measuring the flow time of a hundred grams of sample through a certain pouring nozzle.

Operating Principle of the PTG-S5

The PTG-S5 is broadly used for the comparison of batches of powders perhaps supplied by the same manufacturer over a period of time or for similar materials provides by different suppliers. The flow characteristics are quickly and easily determined as a quality control tool for inter-batch reproducibility, since this may have a separate bearing on the ease of production especially if powders are capable of cohesion and agglomeration over time.

Features

1. Fully USP <1174>, EP <2.9.36>, EP <2.9.16 and ISO 4324 (12/83) compliant

2. Measure flow-time, cone angle, flowability, cone density and cone volume

3. PTG-ER stirrer included

4. Integrated analytical balance cell

5. Integrated dust protection bonnet

6. Built-in printer

Advantages

1. Reduce process costs

2. Improve product consistency from batch to batch

3. Keep tight control of component powders, especially if they are natural products

4. Compare sources of powdered products

5. Provides an easy method to achieve quality control on bulk incoming component products

6. Provides an easy method for the control of dry and wet mixing, tableting, granulating, and capsule filling

7. Predict powder transport through conveyors, air lifts and in silos

8. Predict powder suitability for capsule and bottle filling

9. Predict product settling during transport, so called classification

10. Predict powder influence on tablet hardness and solid dosage form stability

11. Predict powder influence on tablet disintegration and friability

12. Integrated clear view dust protection dust protection hood