Product

Complete outstanding quality and functionality are delivered through METTLER TOLEDO's comprehensive range of laboratory balances and analytical instruments that provides users with flexibility and precision.

Heater Tube Scanner

Heater Tube Scanning is an essential diagnostic process used to evaluate the internal condition of fuel heater tubes in refining and petrochemical operations. These tubes are exposed to extreme temperatures and complex hydrocarbon flows, leading to fouling, coking, and oxidation over time. Through high-precision scanning, the system provides non-destructive measurement of deposit thickness, corrosion patterns, and surface degradation, ensuring early detection of performance issues. This enables operators to plan maintenance proactively, avoid costly shutdowns, and maintain the efficiency of heat transfer systems critical to refining operations.

The technology is built around advanced optical and imaging sensors that deliver high-resolution mapping of tube interiors. The scanning process captures detailed measurements of tube geometry, wall integrity, and deposit accumulation with micrometer accuracy. This allows engineers to visualize and quantify changes over time, identify hot spots or areas of accelerated wear, and establish accurate baselines for predictive maintenance programs. The ability to measure tube degradation without physical intrusion ensures that inspection can be performed safely and efficiently, even in demanding industrial environments.

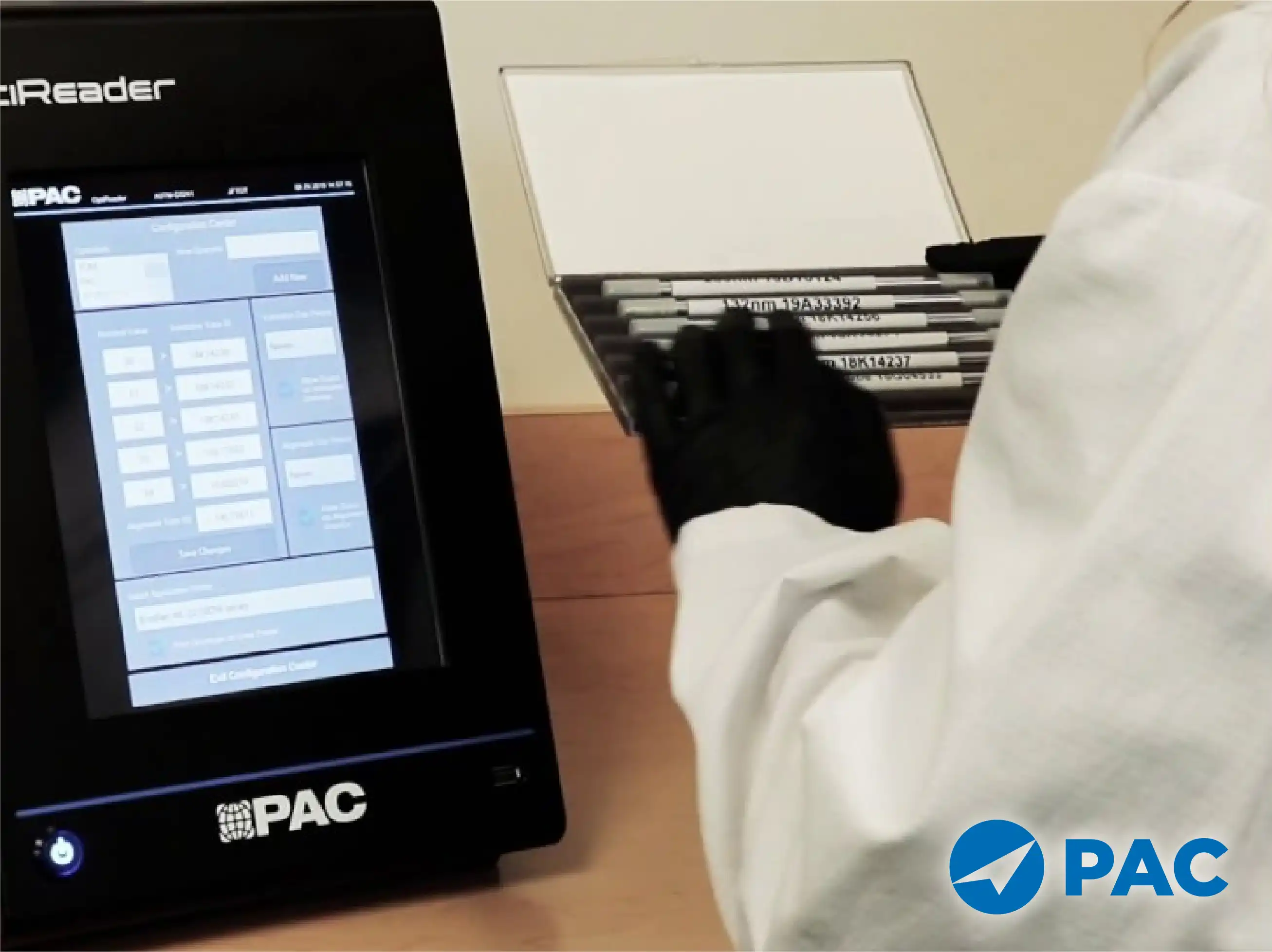

Automated positioning and scanning mechanisms enable precise and repeatable results across multiple tubes. The system can accommodate a variety of tube diameters and configurations commonly used in refinery furnaces and heat exchangers, maintaining accuracy across complex geometries. This automation reduces operator dependency, minimizes the potential for human error, and standardizes inspection procedures across different facilities. The result is consistent, reliable data that supports asset integrity management and operational decision-making.

Real-time data acquisition and visualization are central to the heater tube scanning process. The system generates comprehensive 2D and 3D representations of the inner surface, illustrating deposit thickness, material density, and corrosion progression. These digital profiles allow engineers to compare current tube conditions with historical scans, track performance trends, and forecast future degradation rates. Such analytical insights form the foundation for advanced predictive maintenance strategies that extend tube life and optimize cleaning intervals.

The scanner’s design ensures safe operation under high-temperature conditions typically found in fuel heating systems. Constructed with robust materials and equipped with thermal protection features, it can operate near hot surfaces without affecting accuracy or safety. Its non-invasive measurement technique eliminates the need for tube cutting or system depressurization, allowing inspections to take place during scheduled maintenance or between production cycles, reducing downtime and improving throughput.

Advanced analytical software complements the hardware system by providing intuitive visualization and data processing capabilities. Users can analyze deposit growth, generate automated reports, and calculate key performance indicators such as heat transfer efficiency loss or cleaning thresholds. The integration of digital data management tools also supports compliance with refinery inspection standards and facilitates traceability within maintenance documentation systems, improving transparency and quality control.

The precision of the heater tube scanning technology enables early identification of potential failure zones and localized overheating areas. This insight allows process engineers to adjust furnace operating conditions, optimize fuel-air ratios, and implement cleaning or chemical treatment programs before severe damage occurs. Consequently, refineries experience improved thermal efficiency, reduced energy consumption, and extended service life of critical components, all while maintaining consistent production quality.

By combining high-resolution sensing, automated control, and advanced data analytics, the Heater Tube Scanner delivers a complete inspection and diagnostic solution for refinery heater tubes. It ensures operational reliability, reduces maintenance costs, and supports continuous process optimization. The technology represents a significant advancement in refinery asset management, enabling safer, cleaner, and more energy-efficient operations through accurate and repeatable tube condition assessment.