Versati™ Tabletop Ventilated Centrifuge

Esco Lifesciences

ESCO Versati™ Centrifuge

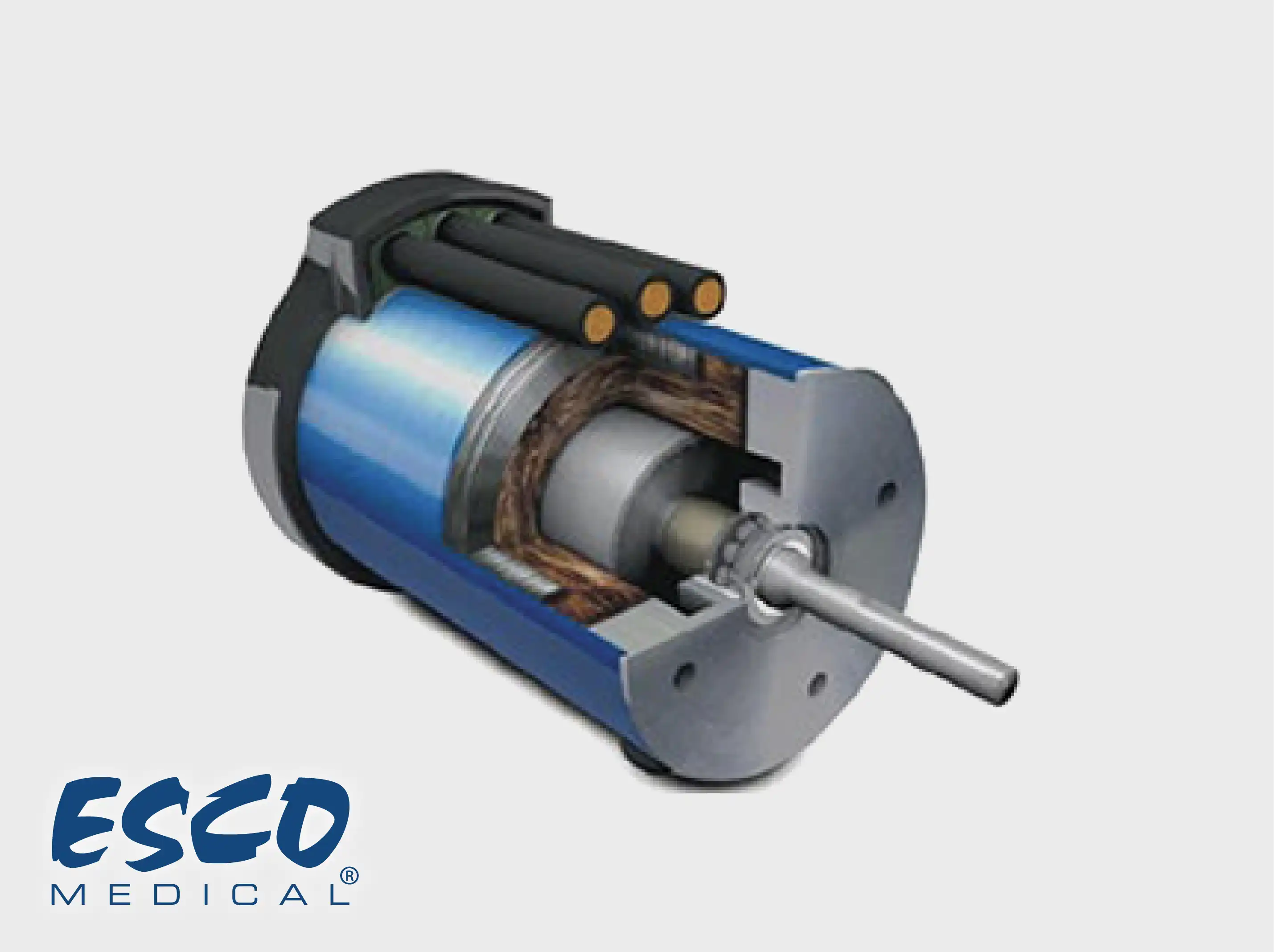

The operational features of the unit further address common pain points in busy laboratory environments. The Versati™ model incorporates an intelligent microprocessor control system with a large LCD and rotary knob for intuitive setup and monitoring. Safety is addressed via the Genuine-Protec™ safety lid design and V-balance™ automatic imbalance protection, helping to minimize downtime and reduce the risk of accidents or sample loss. The motor is maintenance-free (brushless, German technology) so there’s no need for bearing replacement or oil changes, saving on service costs and interruptions. Additionally, the Isocide™ antimicrobial powder coating ensures that 99.9% of surface bacteria are eliminated within 24 hours of exposure, supporting clean-lab environments and reducing contamination risk.

When running centrifuges continuously in a lab environment, users often face issues such as excessive vibration or noise, which can affect the workplace or compromise samples. The Versati™ addresses this with its V-balance™ system that automatically detects imbalance and halts or slows down the rotor to prevent damage or accidents. This translates into improved operational safety and less downtime from maintenance or failed runs.

Laboratories handling multiple sample formats,tubes, micro-plates, etc.,often incur delays and errors when switching rotor types and adapting hardware. Versati™ offers flexibility in rotor selection (fixed-angle up to 6 × 250 mL, swing-bucket up to 4 × 250 mL, microtiter up to 6 plates) allowing one instrument to service many workflows, reducing instrument footprint, downtime and complexity. Traditional centrifuges require frequent servicing,bearing replacements, oil changes, bearing noise, leading to interruptions in work. The Versati™ features a maintenance-free, German-origin brushless motor that eliminates the need for those service routines, reducing cost and increasing uptime, making it an excellent choice for research labs or high-throughput environments.

When dealing with precise applications like DNA precipitation or cell preparation, you need rapid acceleration and fine control of speed and time. Versati™ includes an intelligent microprocessor control system with a large LCD and big rotary knob for intuitive and rapid setup and monitoring, reducing human error and facilitating consistent performance. Safety when operating a centrifuge isn’t optional, any lid failure or rotor mismatch can result in physical damage or sample loss. Versati™ addresses this with a Genuine-Protec™ safety lid design and Smartdrive™ rotor auto recognition system that restricts the installed rotor from being set beyond its maximum speed for motor protection.

Maintaining a high level of cleanliness and minimizing cross-contamination is a recurring challenge in biotech and IVF labs. Versati™ uses an Isocide™ antimicrobial powder coating that eliminates 99.9% of surface bacteria within 24 hours, supporting biosafety compliance and reducing contamination risk.

Often lab bench space is limited, and large centrifuges can consume valuable workspace or complicate access. Versati™ is engineered with a compact footprint and strong capability, allowing installation on the bench without sacrificing workspace or usability. This is especially important in research labs or clinics handling multiple complex instruments in tight spaces. In workflows involving sensitive data or precious samples, you need high-yield pelleting and reliable separation to avoid repeat runs. Versati™ delivers powerful separation performance across tubes and plates, meaning faster turnaround, reproducible results and fewer repeated runs, translating directly into time and cost savings over the long term.

read more about ESCO Versati™ Centrifuge here