Home » Products » Mechanical Testing » Impact Drop Towers & Pendulums » Instron Drop Weight Impact Testers

Impact testing machine

Complies with all impact testing standards

Instron Drop Weight Impact Testers

Introducing the next generation of impact testing machines - the Instron 9400 Series Dynatup drop weigh machine! Discover the power of a drop weight impact testing machine! This incredible tool accurately measures the energy needed to break or damage a material. By dropping a defined weight onto a specimen or component from a specific height, you can determine the impact energy and velocity with precision.

Puncture Test Method and Other Impact Test Methods

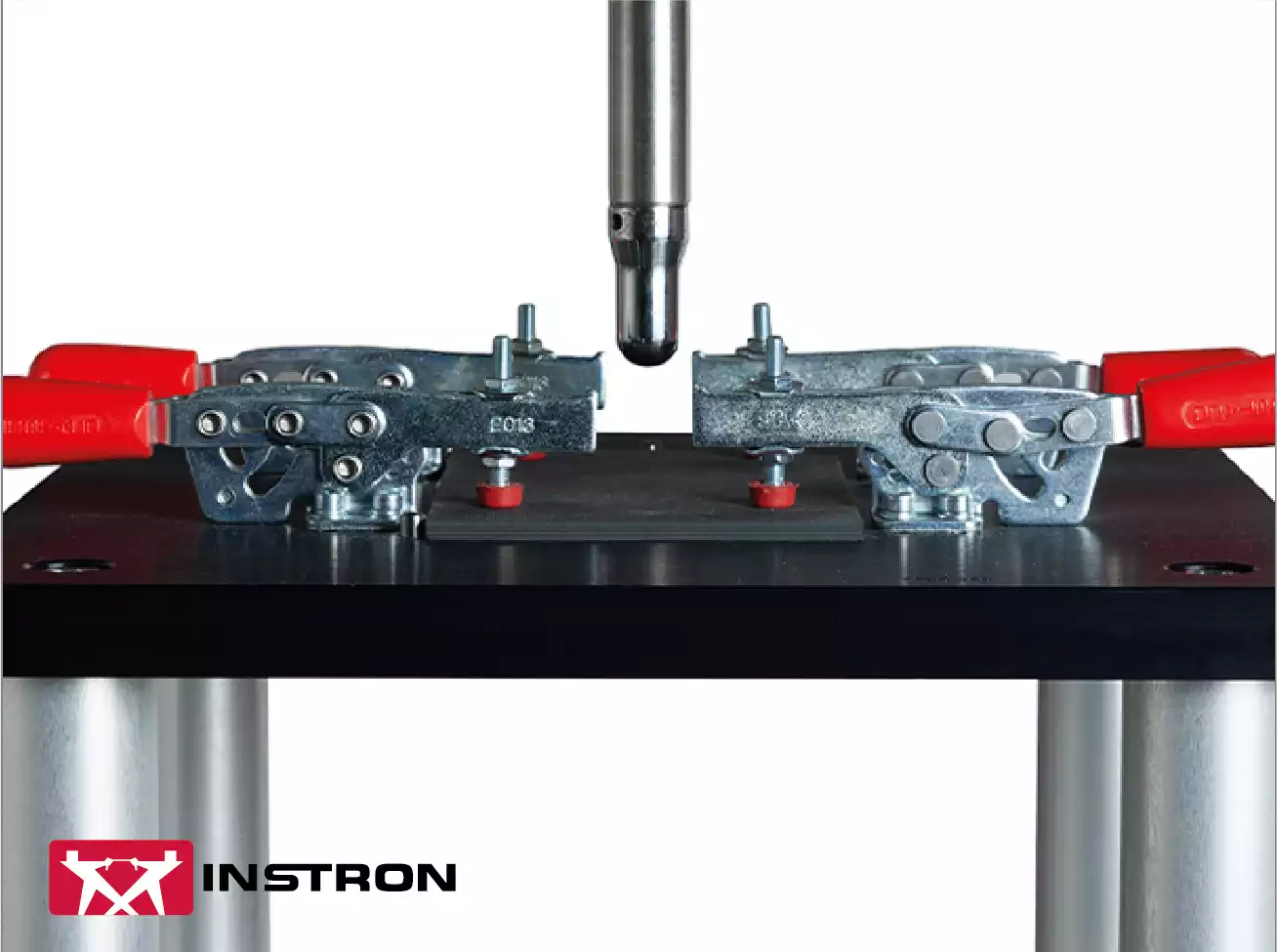

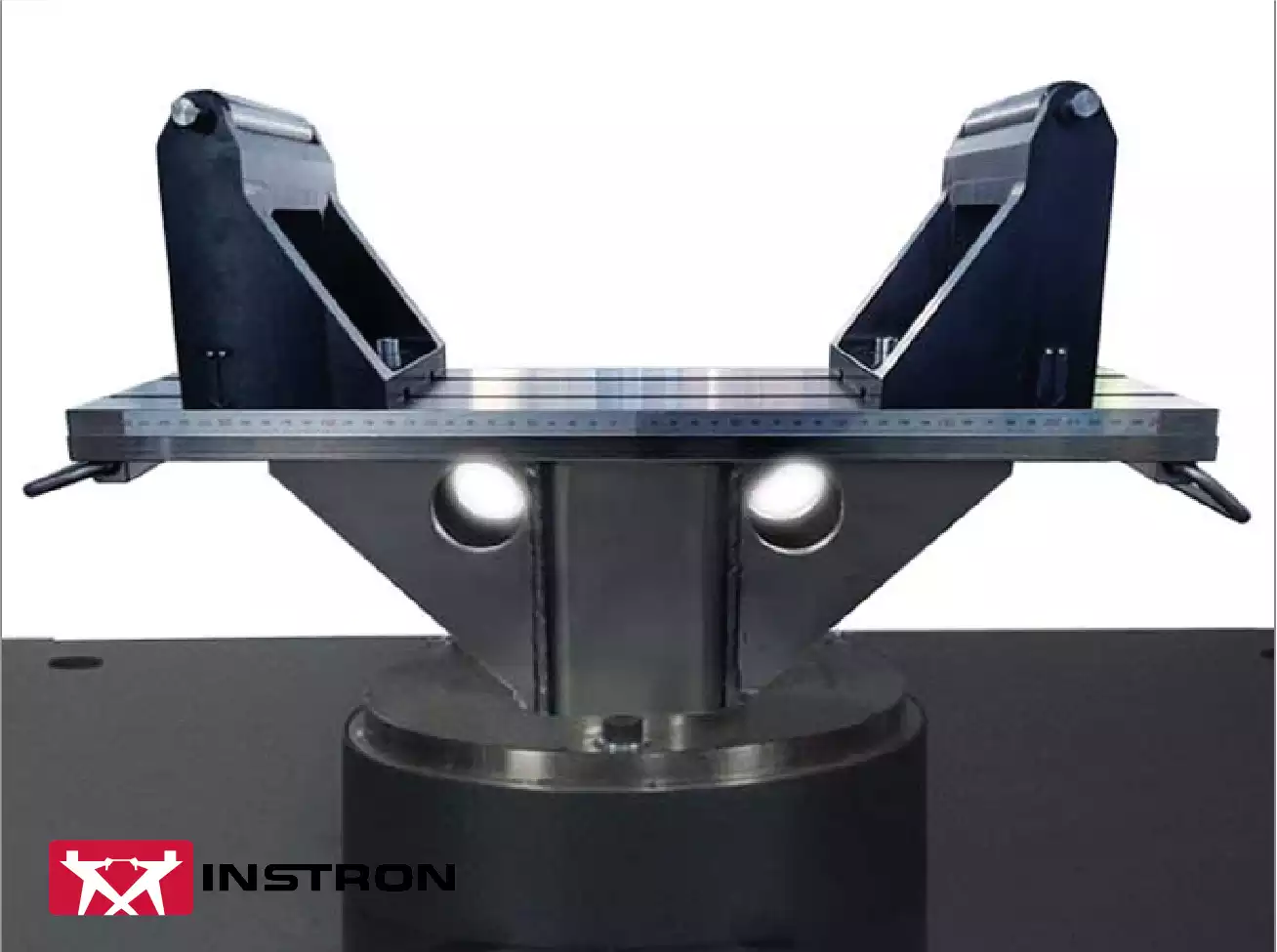

Discover the top drop weight impact test methods used by industry experts, including the Puncture Resistance Test, CAI Test (Compression After Impact), Tensile Impact Test, 3 Point Bending Test, and Wedge Peel Impact Test. Our advanced testing methods accurately measure the durability of polymers, including load-deflection curves and total energy absorption during impact events. Discover the top ISO and ASTM standards for impact testing of plastics! These include the multi-axial impact test (ASTM D3763), puncture resistance test method (ISO 6603), CAI test method (ASTM D7136), wedge peel impact test method (ISO 11343), and tensile impact test method (ISO 8256).

Tests include:

- Puncture Resistance Test

- Compression After Impact (CAI ) Test

- Tensile Impact Test

- Adhesive Peel Impact Test

- 3 Point Bending Test

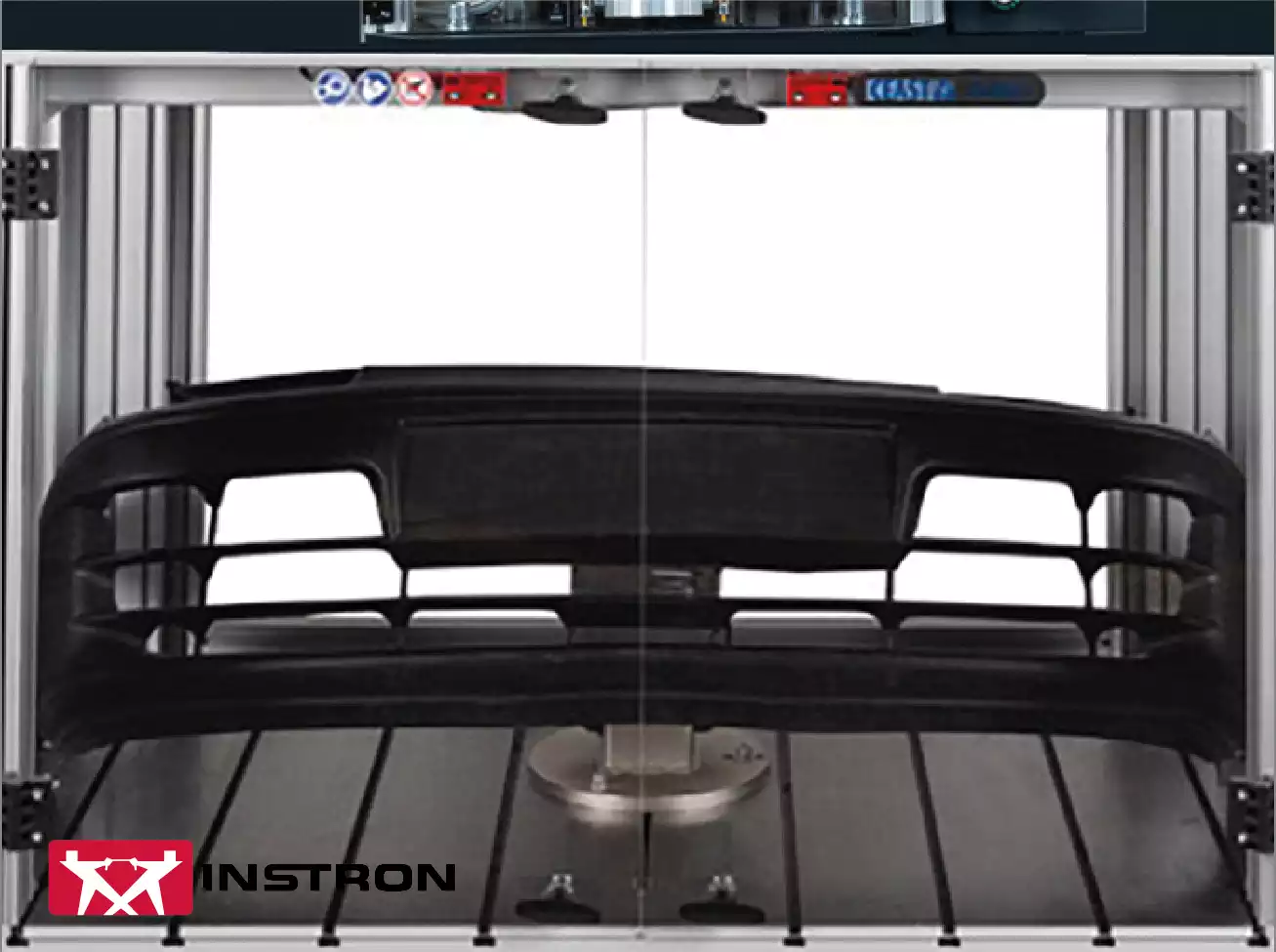

- Component/Finished Products Test

Start Testing Faster

Experience unparalleled ease-of-use with Bluehill® Impact software and its intuitive touchscreen dashboard. Our software guides users through every step of the testing process with clear, concise instructions, ensuring that tests are always repeatable, effortless, and error-free.

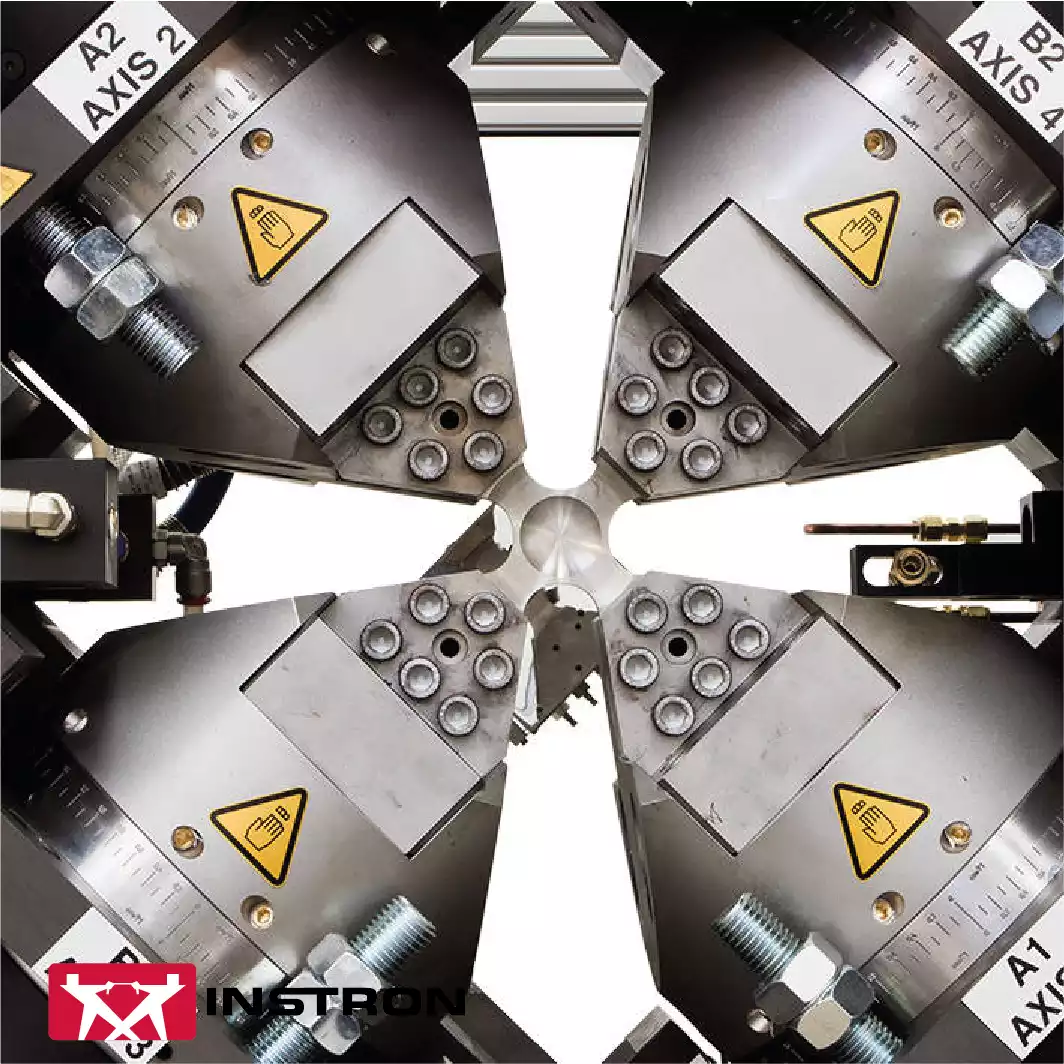

Simplified Flexibility

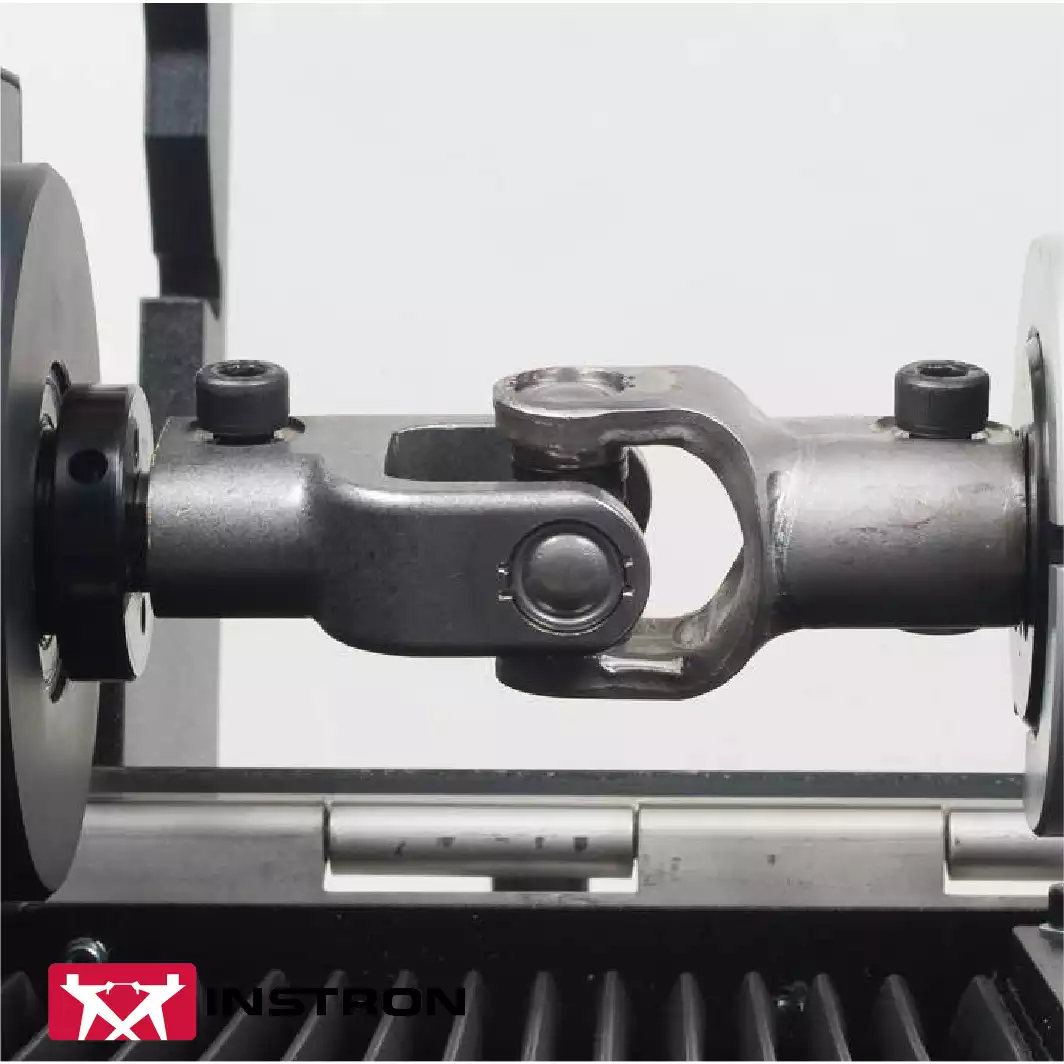

Unlock the full potential of your Instron drop weight impact testing machine with our extensive selection of interchangeable supports, masses, fixtures, and accessories. Our top-of-the-line products enable you to conduct a variety of tests, including puncture resistance, tensile impact, and wedge peel impact, as well as compressive and component testing. Experience unparalleled versatility and precision with our cutting-edge equipment.

Speed up Collaboration

Effortlessly transition between assignments with Bluehill Impact's cutting-edge file management system. Share your test methods and results seamlessly with both your colleagues and clients, streamlining your workflow and enhancing productivity.

Extended Capabilities

Experience the unparalleled performance of the Instron drop weight impact testing machine! Our state-of-the-art equipment boasts energy capacities and test space that are perfectly tailored to meet the most commonly performed impact test methods in a variety of industries, including Raw Materials, Automotive, Aerospace-Aviation, Defense, Electronics, and Consumer Products. With the ability to test a wide range of materials, our machine is the ultimate solution for all your impact testing needs.

Handle the Most Demanding Analysis

Experience unparalleled testing capabilities with the 9450 drop weight impact testing machine. Expand your horizons with the ability to achieve 24 m/s impact velocity, extra wide test chambers, and high-speed cameras that ensure no impact test event goes unnoticed.

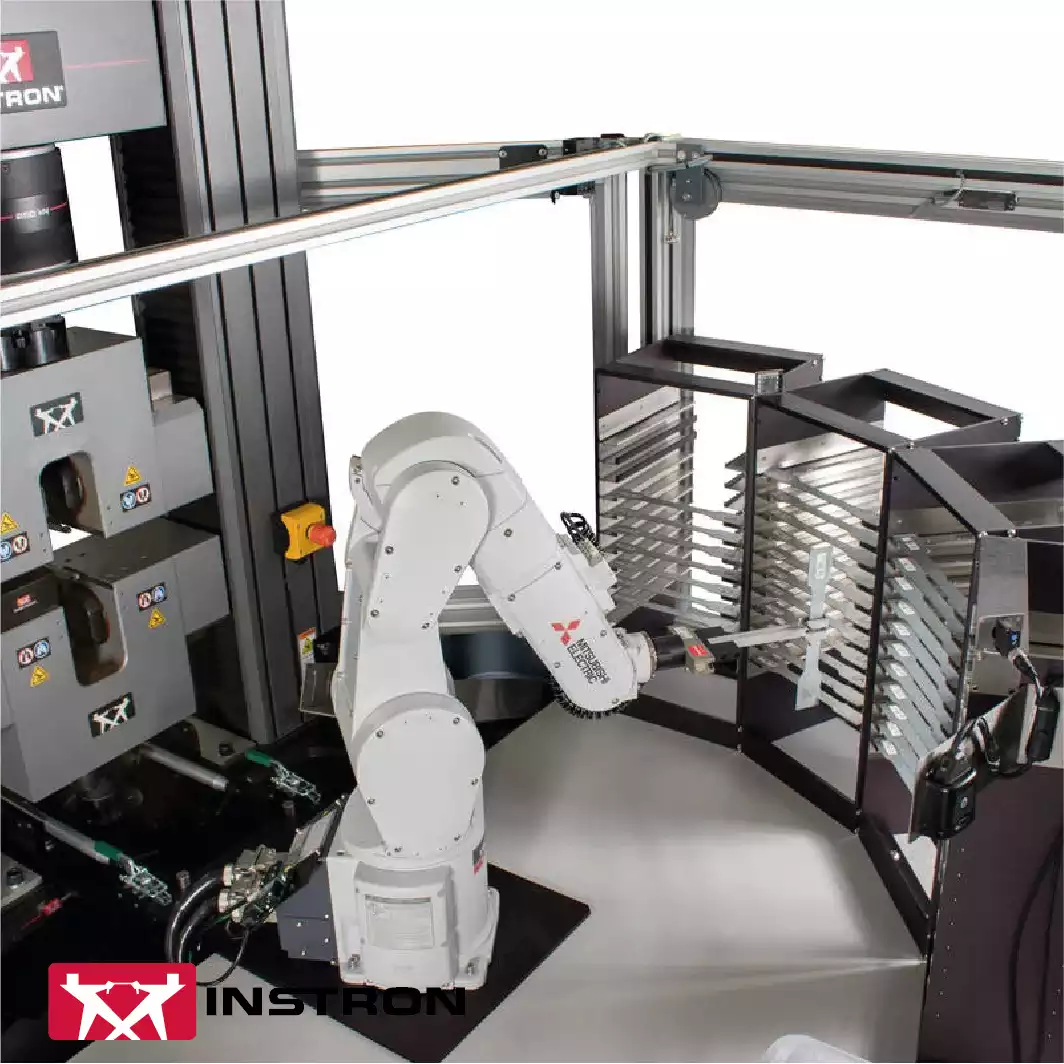

Faster Time to Market

Experience the benefits of continuous testing and validation for your newly developed materials with our cutting-edge automated testing technology. Accelerate your product's time-to-market with reduced testing cycles.

Read more about Instron Drop Weight Impact Testers here

Related Products

Ask Us A Question

Subscribe to our Newsletter

Receive all our promotions, updates, news and much more...

CONTACT US

Diamond Spectrum for Scientific & Laboratory Equipment Co

Jeddah

Khobar

Taawon Group © 2024 - All Rights Reserved

We use cookies to optimize site functionality and give you the best possible experience

.webp)