Home » Products » Mechanical Testing » Dynamic and Fatigue Testing Systems » Instron High Strain Rate VHS Systems

High Speed Testing

Identifying the most optimal design for weight

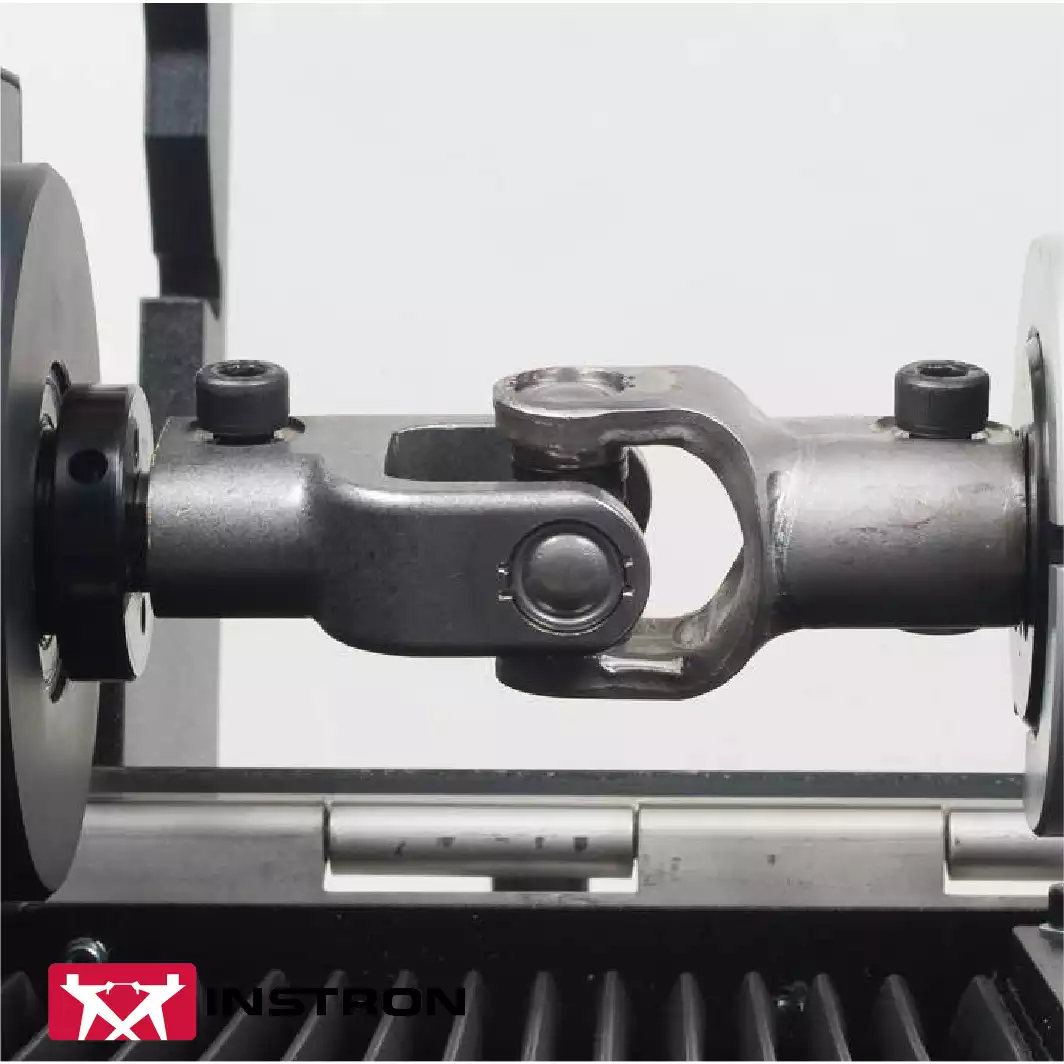

Instron High Strain Rate VHS Systems

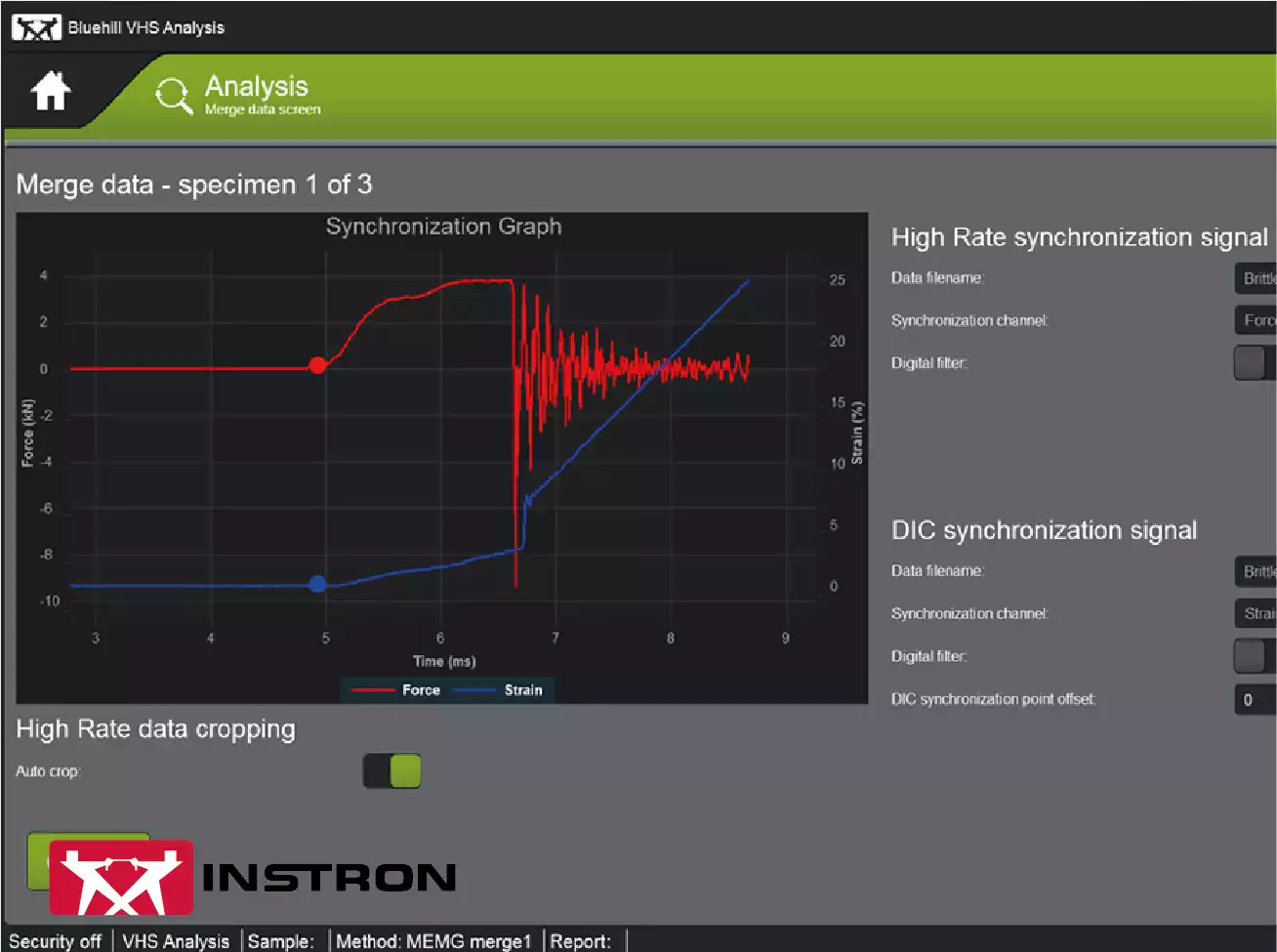

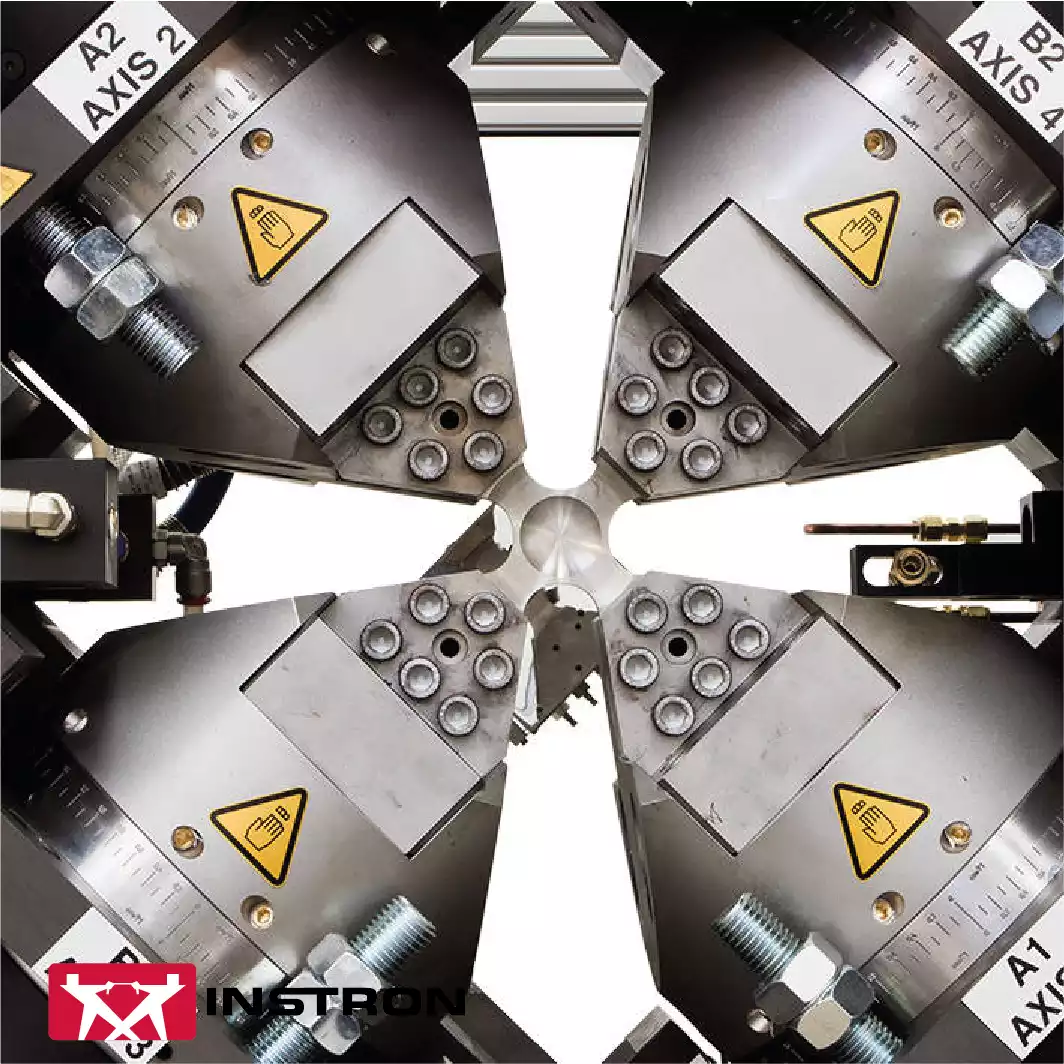

Learn how different materials behave in unexpected ways when subjected to varying strain rates, providing insight into the qualities that are influenced by this variable. In applications in which components are subjected to high strain rates, characterization of these dynamic properties across a wide range of velocities becomes highly critical. This is especially true when researching material failure and also determining which design is the most optimal in terms of weight.

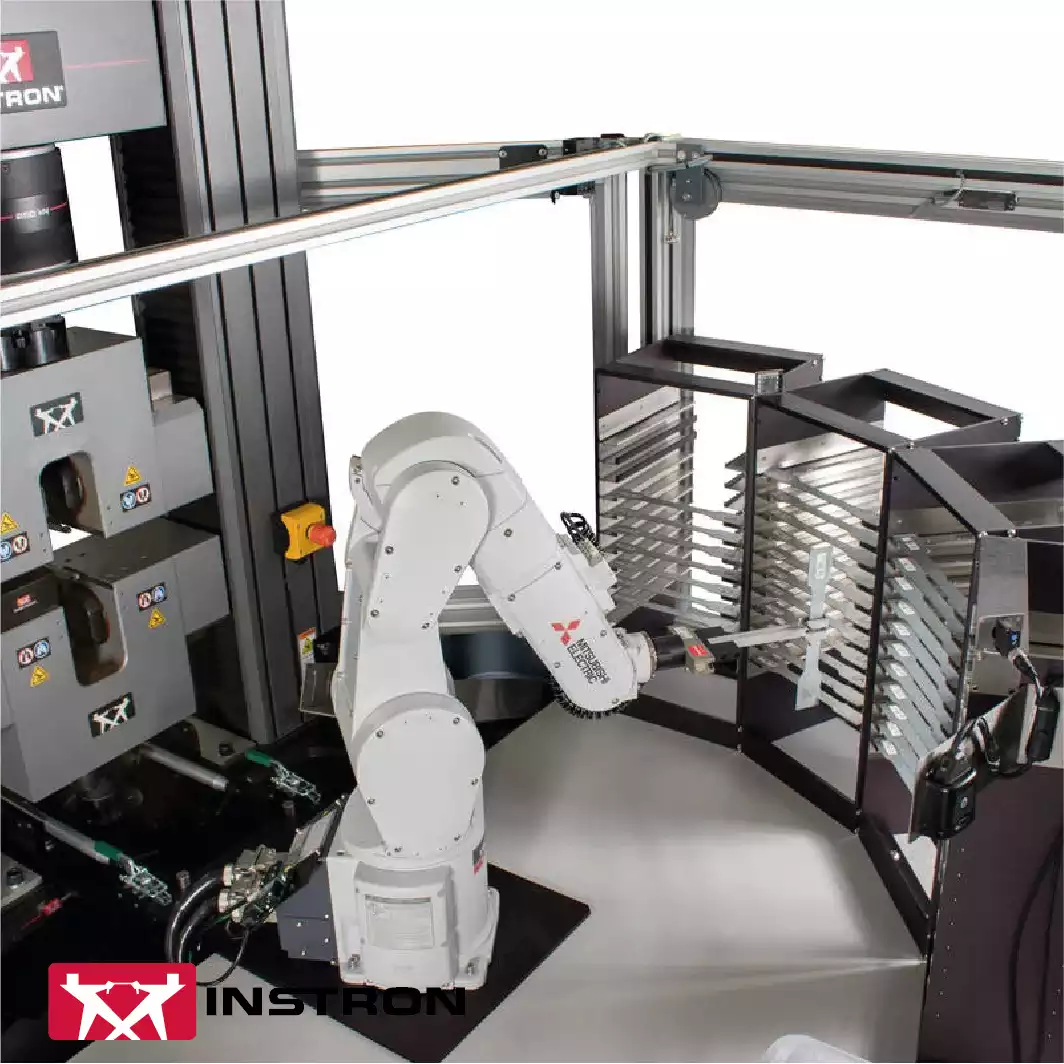

Your industry is going to undergo a dramatic shift as a result of the high strain rate testing devices that we provide. Even while working in environments with high strain rates, you will have the self-assurance to design components and accurately forecast how materials will behave. Invest in our cutting-edge technology right now so that you may stay ahead of the curve despite the unpredictability of the real world. Impact with a high strain rate might be experienced by one or more of a product's components in a wide variety of contexts. Some examples include the landing gear on aircraft, the crash impact of a vehicle on the road, or even the rope strings that are pulled to deploy a parachute. These components have to meet all of the pertinent safety and industry regulations in order for the company to remain competitive in this market. As a result, in order to construct goods that are both safe and functional and to validate the accuracy of the computer simulation tools, such as a vehicle crash simulation, a high strain rate testing machine that is capable of performing operations in a dependable manner and collecting data with high levels of accuracy is required.

Read more about Instron High Strain Rate VHS Systems here

Related Products

Ask Us A Question

Subscribe to our Newsletter

Receive all our promotions, updates, news and much more...

CONTACT US

Diamond Spectrum for Scientific & Laboratory Equipment Co

Jeddah

Khobar

Taawon Group © 2024 - All Rights Reserved

We use cookies to optimize site functionality and give you the best possible experience

.webp)